Enterprise Resource Planning (ERP) in Manufacturing: Transforming the Industry

In today’s fast-paced industrial landscape, the success of manufacturing businesses often hinges on how well they adapt to technological advancements. Did you know that companies implementing Enterprise Resource Planning (ERP) in Manufacturing experience an average 20% increase in operational efficiency? If you’re in the manufacturing sector, understanding ERP systems is no longer optional; it’s essential. This blog will explore how ERP can revolutionize manufacturing operations, enhance productivity, and give businesses a competitive edge

What is ERP, and Why Does It Matter in Manufacturing?

ERP systems are integrated software solutions that manage and automate business processes, from inventory control to production planning. For manufacturers, ERP systems unify operations into a centralized platform, streamlining workflows and improving decision-making.

Key benefits of using Enterprise Resource Planning (ERP) in Manufacturing include:

- Real-Time Data Access: Immediate insights into inventory levels, production status, and financials.

- Enhanced Collaboration: Seamless communication between departments, suppliers, and customers.

- Cost Efficiency: Reduction in wastage and operational costs through optimized resource allocation.

- Scalability: Easy adaptability to accommodate business growth.

Discover how ERP systems can cater to your unique needs by exploring Sodio’s custom ERP development services.

The Core Features of ERP Systems for Manufacturing

A well-implemented ERP system comes equipped with several modules tailored to the needs of manufacturers. Let’s break down the essential features:

- Inventory and Supply Chain Management

- Automates stock tracking and procurement.

- Reduces instances of overstocking or stockouts.

- Production Planning and Scheduling

- Provides tools for planning production runs efficiently.

- Ensures optimal use of machinery and labor.

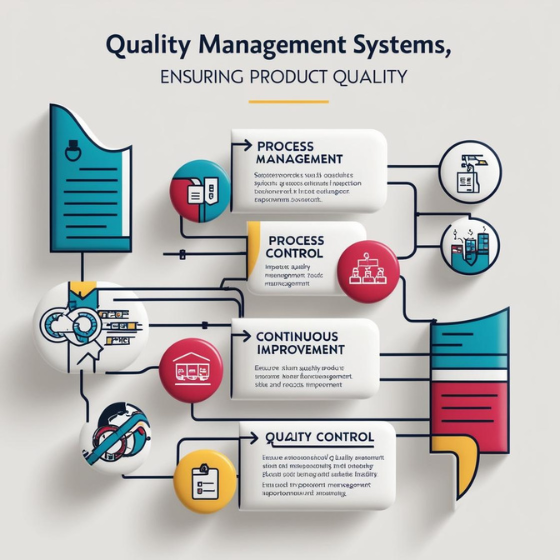

- Quality Control

- Tracks quality metrics at every production stage.

- Enables swift corrective actions for defective products.

- Financial Management

- Integrates budgeting, payroll, and expense tracking.

- Simplifies regulatory compliance and reporting.

- Customer Relationship Management (CRM)

- Enhances after-sales service and customer satisfaction.

Incorporating these features into your operations can yield significant ROI. Learn more about Sodio’s ERP consulting services to kickstart your transformation.

Real-World Impact: Case Studies of ERP in Manufacturing

Case Study 1: Optimizing Supply Chain Operations

A mid-sized electronics manufacturer implemented an ERP solution to manage its complex supply chain. The result? A 30% reduction in lead times and an 18% increase in customer satisfaction. By leveraging Enterprise Resource Planning (ERP) in Manufacturing, the company could predict demand more accurately and avoid production delays.

Case Study 2: Enhancing Production Efficiency

A textile manufacturer facing challenges with manual scheduling adopted an ERP system. Automation reduced human errors, streamlined production, and increased overall efficiency by 25% within the first year.

These success stories demonstrate how ERP systems can revolutionize manufacturing processes. Ready to replicate these results? Check out Sodio’s ERP implementation solutions.

Overcoming Challenges in ERP Implementation

While the benefits are substantial, implementing ERP in manufacturing can pose challenges. Here’s how to address common hurdles:

- High Initial Costs

- Solution: Opt for scalable cloud-based ERP systems that reduce upfront investment.

- Resistance to Change

- Solution: Conduct training sessions to familiarize employees with the new system.

- Data Migration Issues

- Solution: Partner with experienced consultants for a seamless transition.

Navigating these challenges becomes easier with a trusted partner like Sodio. Discover our ERP development and integration expertise.

Why Choose Sodio for Your ERP Needs?

At Sodio, we specialize in creating tailored ERP solutions for manufacturing businesses. Our services ensure:

- Customization: Systems built around your specific business processes.

- Expert Support: Dedicated teams to guide you through every step.

- Future-Readiness: Scalable systems designed to evolve with your business.

Don’t just keep up with the competition—stay ahead. Explore Sodio’s full suite of ERP services to transform your operations today.

Key Takeaways

Enterprise Resource Planning (ERP) in Manufacturing is not just a trend; it’s a necessity. From enhancing operational efficiency to ensuring long-term growth, ERP systems offer unparalleled benefits for manufacturers. By integrating real-time data, automating processes, and fostering collaboration, ERP solutions position businesses for success in an increasingly competitive market.

Ready to revolutionize your manufacturing operations? Contact Sodio’s ERP experts to start your journey today. And don’t forget to subscribe to our newsletter for more insights into the latest technological advancements in manufacturing.